A PCBA manufacturer plays a crucial role in the development of modern electronics by assembling circuits that power almost every device we use. From computers to home appliances, automobiles to medical equipment, the importance of reliable PCB assembly is greater than ever. Understanding how a PCBA manufacturer works makes it easier to choose the right partner for your projects and helps ensure long-term product success.

What Is a PCBA Manufacturer?

A PCBA manufacturer is a company that specializes in assembling electronic components onto bare printed circuit boards. Their responsibility is to turn a simple board into a functional electronic module through a careful and precise assembly process. Every PCBA manufacturer handles various stages like soldering, mounting components, testing, and final inspection to ensure the circuit works flawlessly.

These manufacturers rely on advanced machinery, expert engineers, and strict quality standards to deliver accurate and reliable assemblies for different applications. They support businesses in transforming conceptual ideas into physical electronic solutions.

Importance of PCBA in Modern Electronics

PCBA is the backbone of every digital or electronic product, making its quality extremely important. Without high-quality assembly, even the best-designed circuit can fail, resulting in unreliable products. Because electronics are becoming smaller, smarter, and more efficient, the work of a PCBA manufacturer has become more sophisticated.

Whether it is smartphones, industrial robots, or medical devices, the functionality of these products depends heavily on the precision of assembly. A reliable PCBA ensures long-lasting performance, safety, and operational stability.

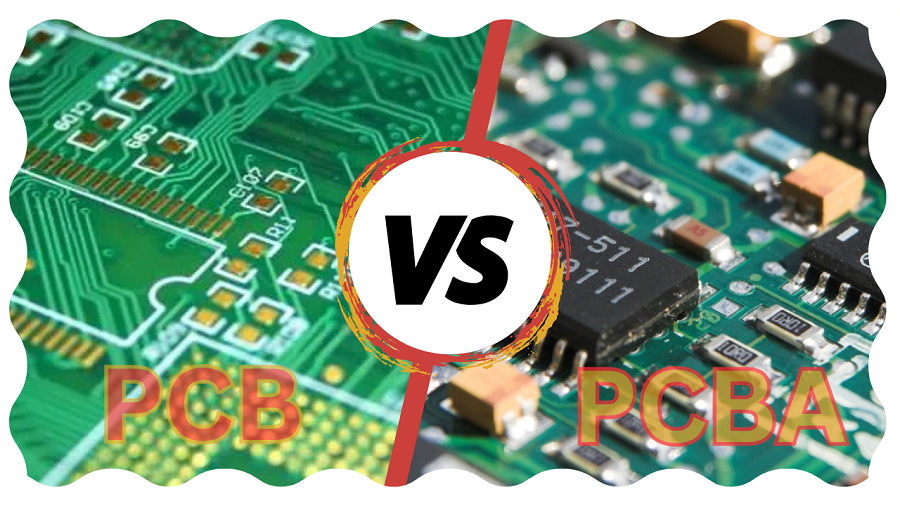

Difference Between PCB and PCBA

Many people confuse PCB with PCBA, but they are not the same. A PCB is simply the bare board made of insulating materials and printed copper tracks. It does not have components installed. PCBA, on the other hand, is the fully assembled board with all electronic parts mounted.

PCBA manufacturers handle this final step of adding resistors, ICs, diodes, and other components to create a complete working circuit. Without PCBA, a PCB is just a non-functional sheet.

How PCBA Manufacturers Work

PCBA manufacturers follow a systematic approach to ensure accuracy and consistency. Their processes combine technology, engineering, and quality control to deliver high-performance assemblies.

Design and Prototyping

Before production begins, manufacturers often assist clients with design reviews and prototyping. This step helps identify errors, ensures design compatibility with manufacturing systems, and reduces production risks.

Component Sourcing

Finding high-quality electronic components is essential. Manufacturers use trusted suppliers and ensure parts meet international standards. Component sourcing also includes verifying availability, price, and compatibility.

Assembly Process

The assembly process may include SMT (Surface Mount Technology), THT (Through-Hole Technology), or both. PCBA manufacturers use automated machines to mount components accurately and conduct soldering with precision.

Testing and Quality Control

Testing is one of the most critical steps. Manufacturers use various testing methods like AOI (Automated Optical Inspection), functional testing, and X-ray testing to identify defects. Strong quality control ensures product reliability.

Types of PCBA Assembly Services

Different assembly methods are used depending on the board design and application.

SMT Assembly: SMT involves placing tiny components on the board surface. It is commonly used for compact and high-density circuits.

THT Assembly: In THT assembly, components are inserted into drilled holes and soldered. This method offers strong mechanical bonding and is ideal for durable applications.

Mixed Technology Assembly: Some boards require a combination of both SMT and THT assembly. Manufacturers use mixed technology to support complex designs.

Key Factors to Consider When Choosing a PCBA Manufacturer

Selecting the right manufacturer ensures product reliability, reduced production costs, and long-term support.

Quality Certifications: Look for manufacturers with certifications such as ISO 9001, IPC standards, and RoHS compliance. These certifications guarantee professional manufacturing practices.

Production Capacity: A good manufacturer should be able to handle small prototypes as well as large-volume production. Their machinery and workforce should support timely delivery.

Technical Support: Strong technical support helps you resolve design issues, malfunction risks, and component choices. A manufacturer with engineers available for assistance adds value to your project.

Benefits of Working with a Professional PCBA Manufacturer

A professional PCBA manufacturer offers accuracy, fast production, quality assurance, and cost-effective solutions. They help reduce production time and ensure every board meets technical specifications. Their expertise allows businesses to avoid errors, reduce waste, and produce more reliable products.

Common Industries Using PCBA Services

PCBA manufacturers support a wide range of industries such as consumer electronics, automotive, aerospace, telecom, medical equipment, and industrial automation. Each sector requires different levels of precision, durability, and functionality.

Challenges PCBA Manufacturers Face

Manufacturers often face challenges like sourcing components during shortages, maintaining consistent quality, and handling complex circuit designs. They must constantly upgrade machinery and follow global standards to stay competitive.

Future Trends in PCBA Manufacturing

The future of PCBA manufacturing is moving toward automation, AI-driven inspection, and miniaturization. As devices become smaller, manufacturers will rely on advanced machines and smarter production methods. Eco-friendly materials and sustainable manufacturing will also play a major role.

Conclusion

PCBA manufacturers are essential partners in the electronics industry. Their expertise ensures efficient assembly, strong performance, and long-lasting durability of electronic products. Whether you are building prototypes or large-scale production, choosing the right PCBA manufacturer makes all the difference. With modern technology and continuous improvement, PCBA manufacturing will keep evolving and supporting innovation across multiple industries.